Overview

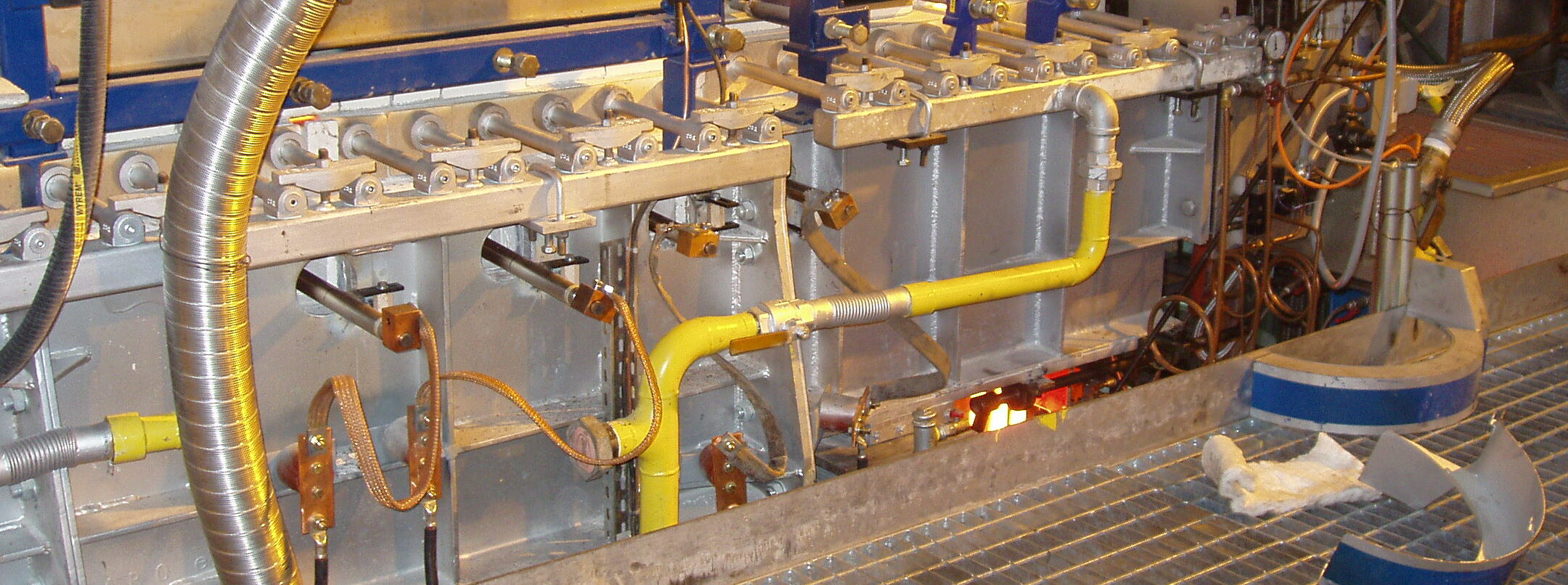

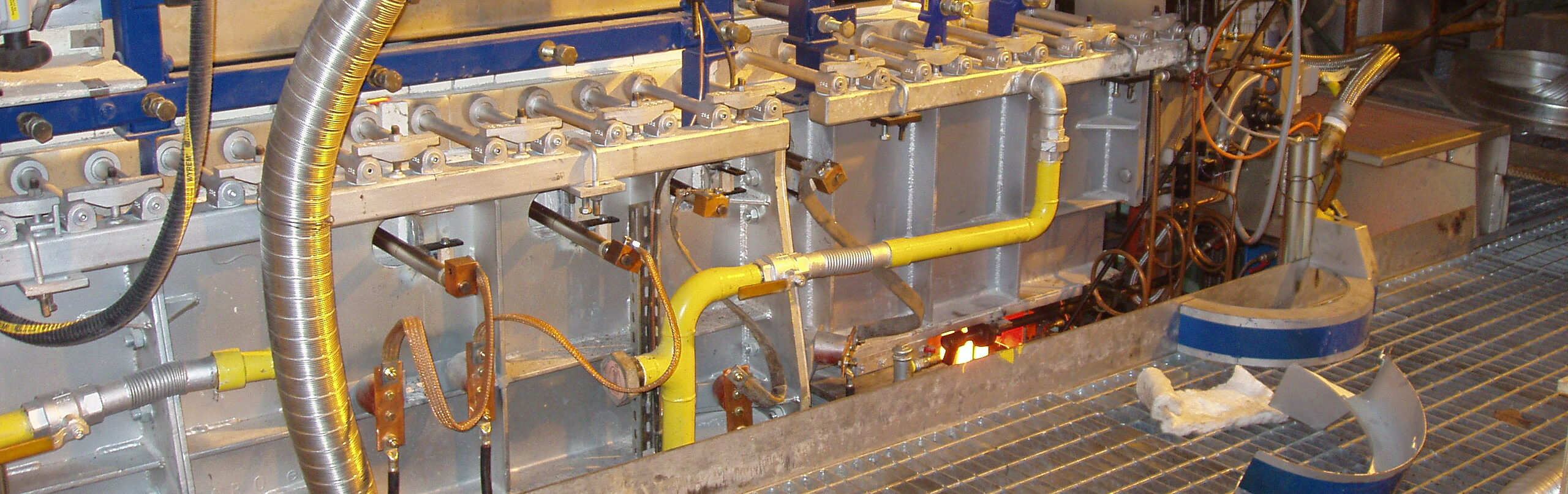

Forehearth thermal conditioning

Forehearth temperature homogenisation system for installation in gas fired or electric forehearths to ensure accurate gob weight and shape control.

Need the brochure in a different language? Request a brochure here.

Specifications

-

For installation in the forehearth conditioning section

-

Proven for effectively removing side to side and top to bottom glass temperature differences

-

Particularly useful in wide forehearths or coloured glass production

-

High installed total power allows quick reaction to changing forehearth conditions

-

Multiple power zones and flexible configurations allow system operation to be tailored to suit individual job parameters

-

Proven installation techniques allow system to be added during operation without the need for draining or cooling down the forehearth

-

Automatic power/temperature and manual control facility for each heating zone

-

Utilises Electroglass’ special design dry electrodes to ensure consistent glass quality without risk of induced DC voltage, a problem common with some other designs

-

Low operating power, typically only a few kilowatts

Glass Types

-

Soda Lime

-

Borosilicates

-

Fluoride Opal

-

Lead Crystal

-

Container

-

Cosmetic

-

Tableware

-

Ovenware

-

Pharmaceutical

-

Tubing

Forehearth Thermal Conditioning

-

Gob weight differences reduced to only a few grams

-

Power to each zone provided by an air cooled, single-phase transformer

-

Electrode overall lengths and immersions to suit individual installations

-

Automatic power control of each zone as standard

-

Automatic temperature control utilising existing in-glass thermocouples

-

Control system bypass for emergency use