Overview

Specialists in all-electric furnaces

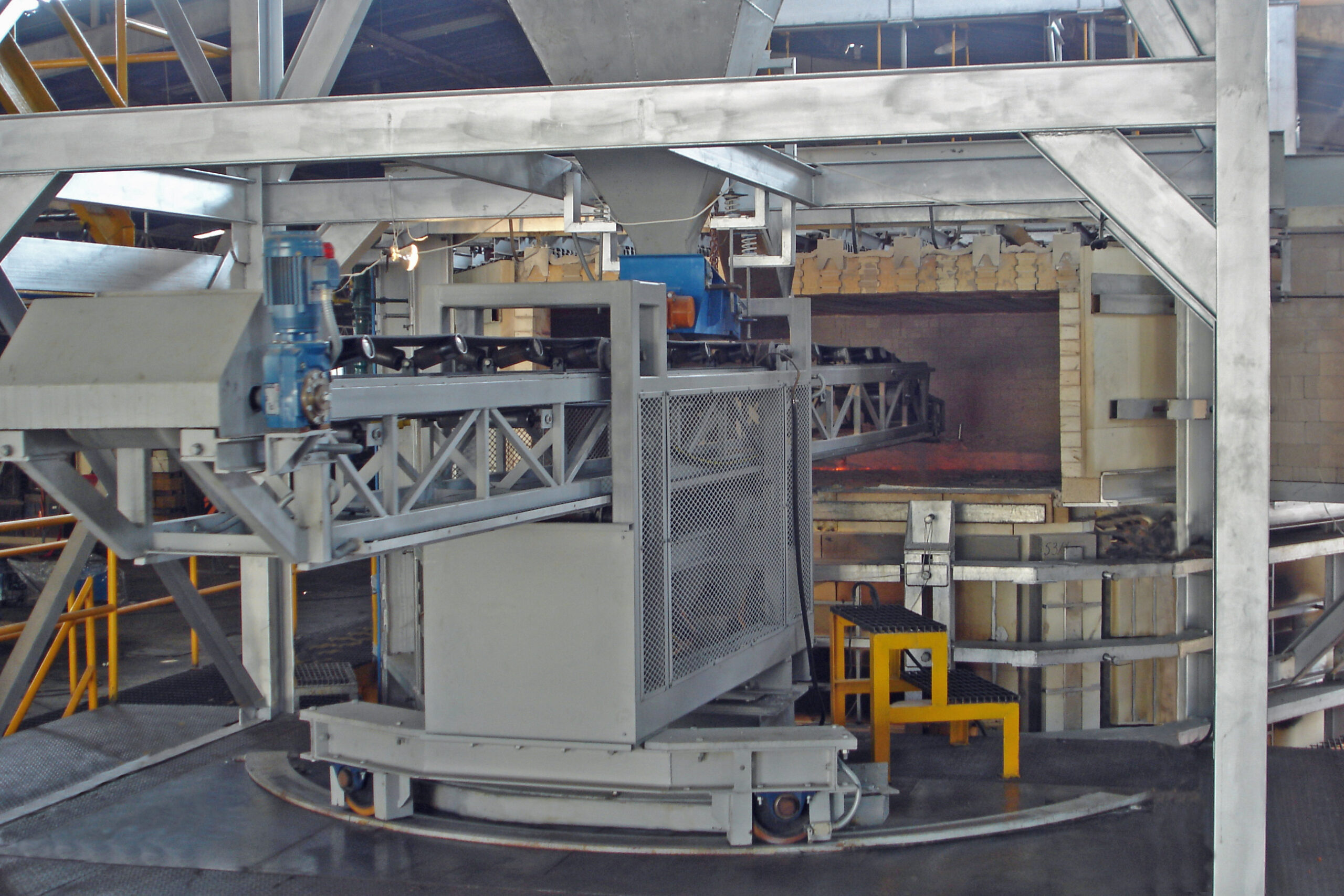

Electroglass has earned a worldwide reputation for technical innovation in the development of All-Electric Furnaces with exceptionally low energy consumption, coupled with high glass quality and flexibility of operation.

Need the brochure in a different language? Request a brochure here.

Specifications

-

Capacities from 200 kg/day to over 250 tonnes/day

-

Cold-top melters with superstructure temperatures typically less than 125 deg.C

-

Exceptionally low energy consumptions, usually 20% to 40% less than other designs

-

Negligible volatilisation and consistent thermal history mean high glass quality

-

Minimal environmental pollution, even from volatile glasses

-

Silent operation

-

Flexible operation with turndown to 50% of rated output or less

-

Ability to withstand long power interruptions without emergency measures

-

Even energy distribution for minimum refractory-glass contact temperatures and low refractory wear

-

Uniform refractory wear pattern and extended furnace life

-

Short cold repair time for maximum productivity

-

Low cold repair costs: glass contact equipment and substructure refractories only

-

No wall cooling or electrode changing required

-

Programmable CNC-controlled batch charging system on most furnaces

-

Critical equipment, such as control panels, electrode holders, batch chargers, designed and manufactured in-house

-

Choice of control systems using advanced PC/PLC technology and user-friendly software with options to suit particular customer requirements

-

Individual physical modelling and design studies carried out for each furnace project

Glass Types

-

Soda Lime flint, green and reduced amber and greens

-

Fluoride Opal

-

Borosilicates

-

Lead Crystal

-

C-Glass

-

Container

-

Cosmetic

-

Tableware

-

Ovenware

-

Lighting

-

Automotive

-

Insulator

-

Potassium Barium

Typical Energy Consumptions

-

850 kWh/tonne for 20 tonnes/day borosilicate cookware

-

780 kWh/tonne for 40 tonnes/day fluoride opal tableware

-

750 kWh/tonne for 80 tonnes/day soda-lime cosmetic

-

720 kWh/tonne for 160 tonnes/day soda-lime container