Overview

Precision controlled bubbling for glass homogenisation

Highly effective and economical method of homogenising glass during the melting process without the risks associated with conventional continuous type bubbling.

Need the brochure in a different language? Request a brochure here.

Specifications

-

Hot-spot bubbling improves thermal and chemical homogeneity in the melt, reducing cord and stone losses

-

Under batch blanket bubbling can improve melt-rate and increase furnace bottom temperatures

-

Reduces the overall time to complete a colour change and homogenises colour during the change

-

Slow precision bubbling eliminates the risk of seed and parasite bubbles in the product

-

Independent control of bubble size and bubbling rate for each bubbler point

-

Throat and distributor bubbling for intermittent use during colour or composition change

-

Unique blockage resistant bubbler tubes allow slow controlled bubbling without the risk of injector damage

-

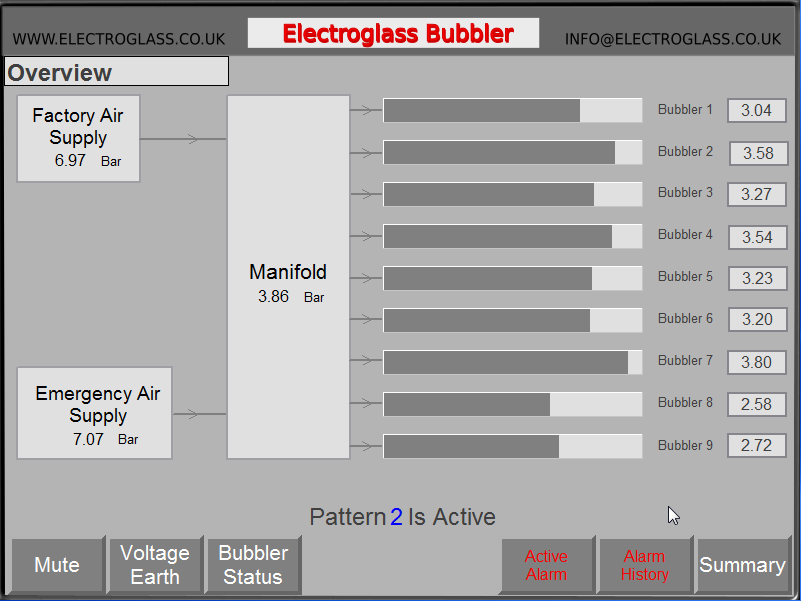

Comprehensive operator interface with touch screen HMI allowing easy access to key system information and control variables

-

Design backed by more than 30 years of continuous development

-

Bubbling can be suspended for prolonged periods and effectively restarted

Glass Types

-

Soda lime

-

Borosilicates

-

TFT

-

LCD

-

C-Glass

-

E-Glass

-

Crystal

-

Container

-

Lighting

-

Tubing

-

Tableware

-

Pharmaceutical

-

TV Panel

-

Float Glass

-

Rolled Sheet

-

Fibreglass

Precision Control Bubbler Systems

-

Bubbler injector tubes available with platinum alloy coating for use in specialist glasses

-

Various bubbling mediums can be used including oxygen

-

Bubbler lengths to suit each installation

-

Volts-to-earth monitoring is included as standard where electric boosting is present

-

The ability to suspend bubbling removes the need for advanceable bubbler tubes currently employed in some applications

-

Bubbler tubes designed to operate for complete furnace campaign with no need for replacement

-

Proven installation techniques allow system to be installed during operation where suitable refractory construction exists

-

Control system can be interfaced with factory computer system on request