Overview

Precision manufactured electrode holders to suit all installation situations

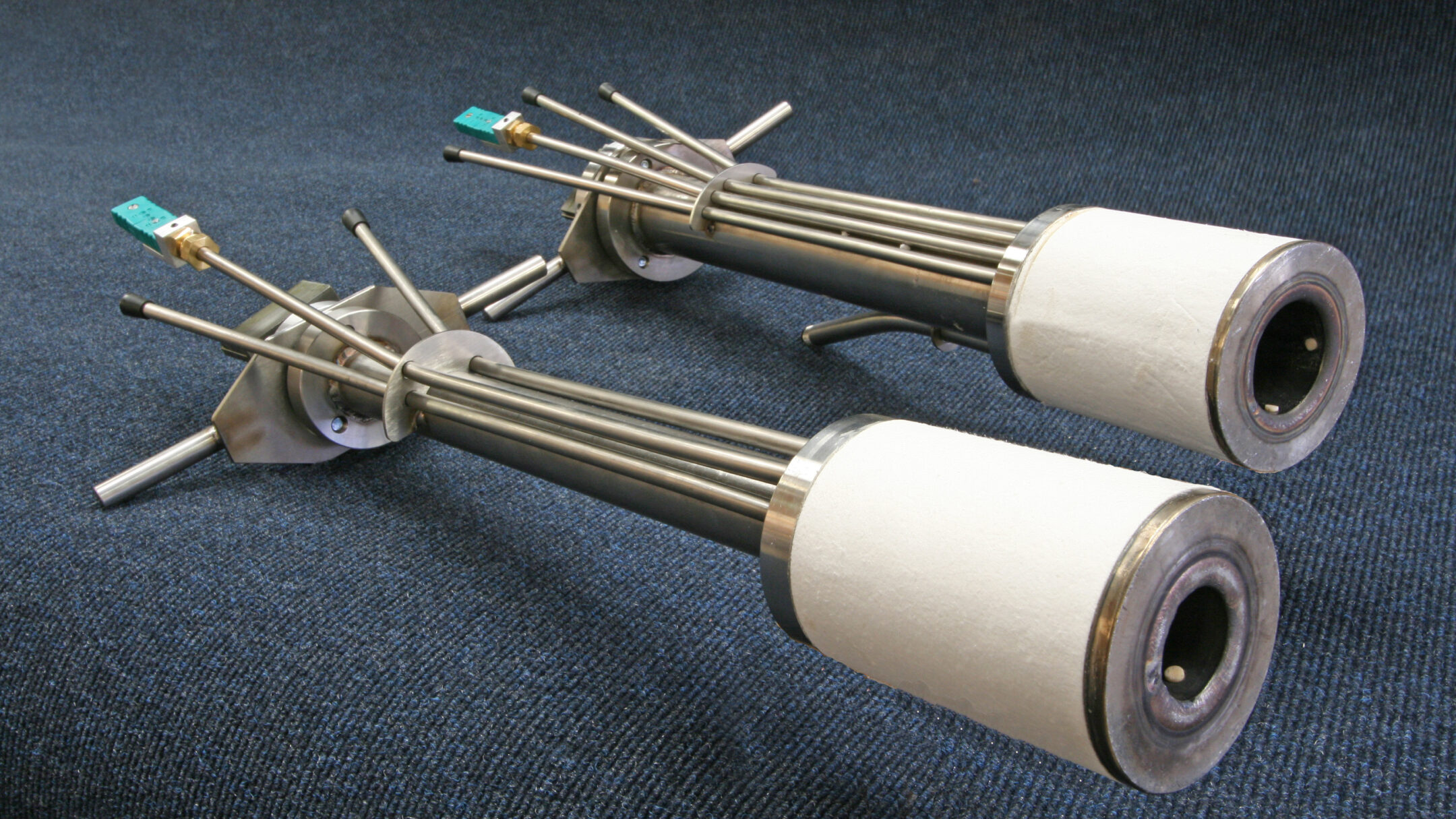

Precision made in our own workshops, using high performance heat resisting steels and with strict quality control, the Electroglass range of holders for molybdenum rod electrodes incorporate many advanced design features for energy saving, refractory protection, electrode cooling efficiency and maintenance free long life.

Need the brochure in a different language? Request a brochure here.

Specifications

-

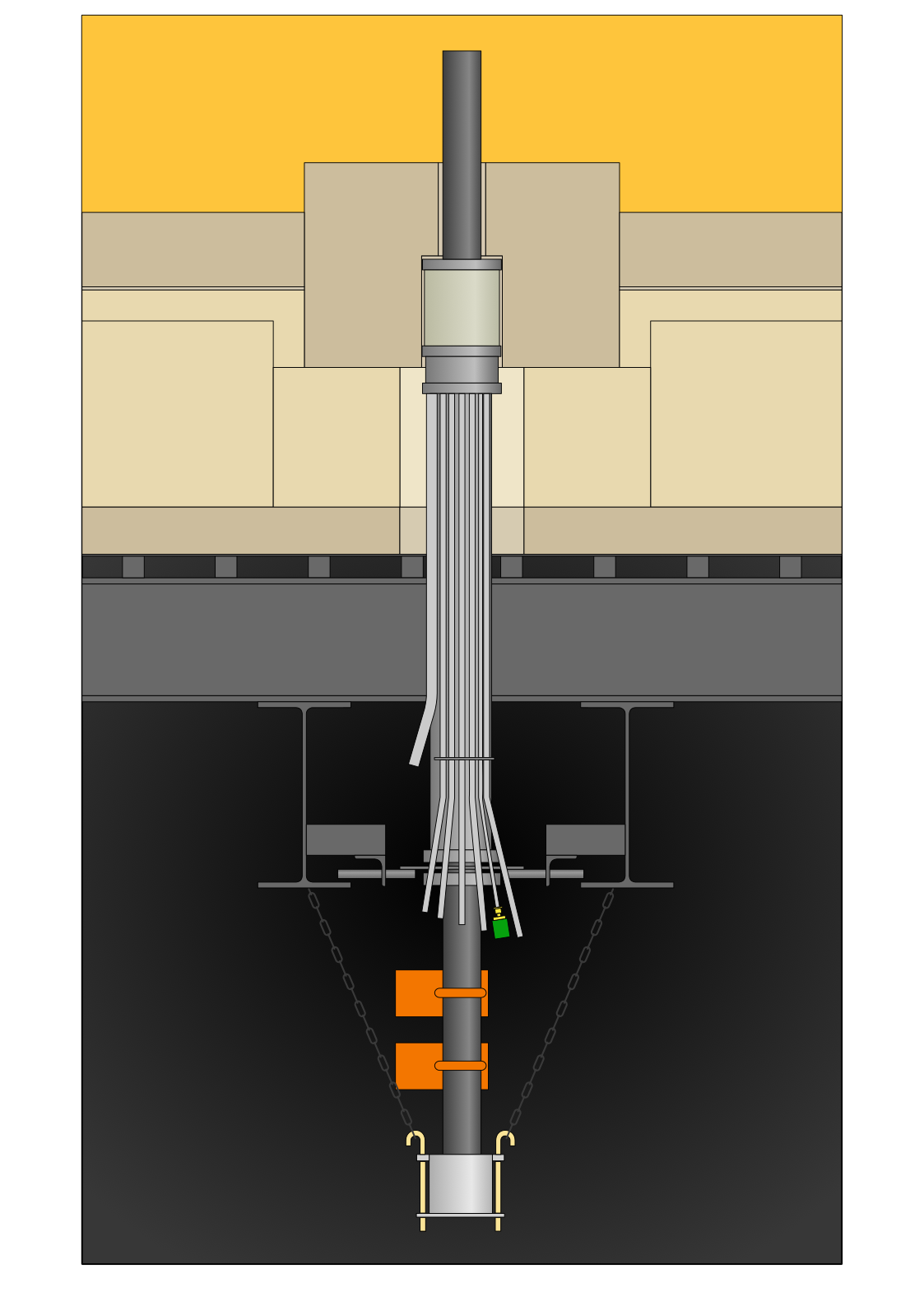

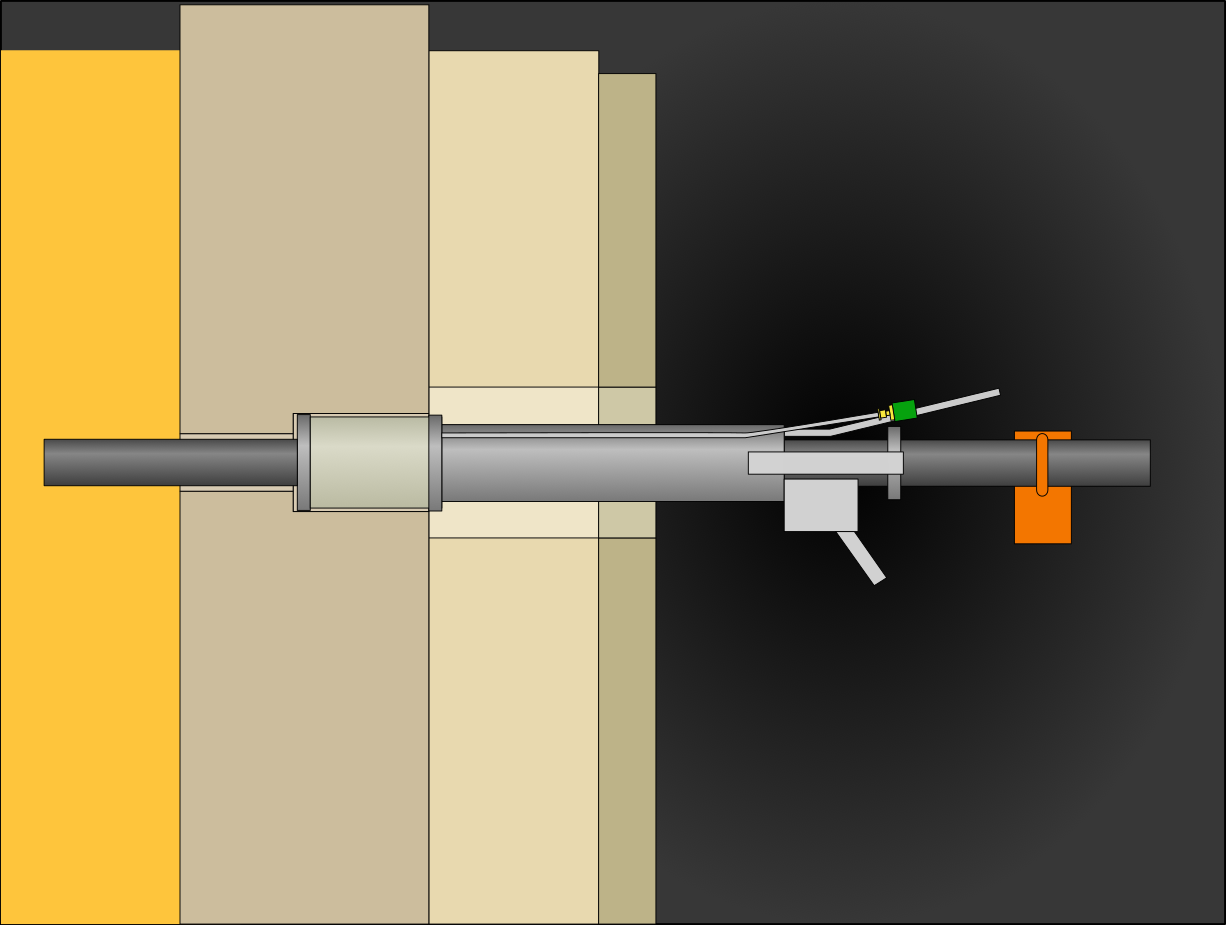

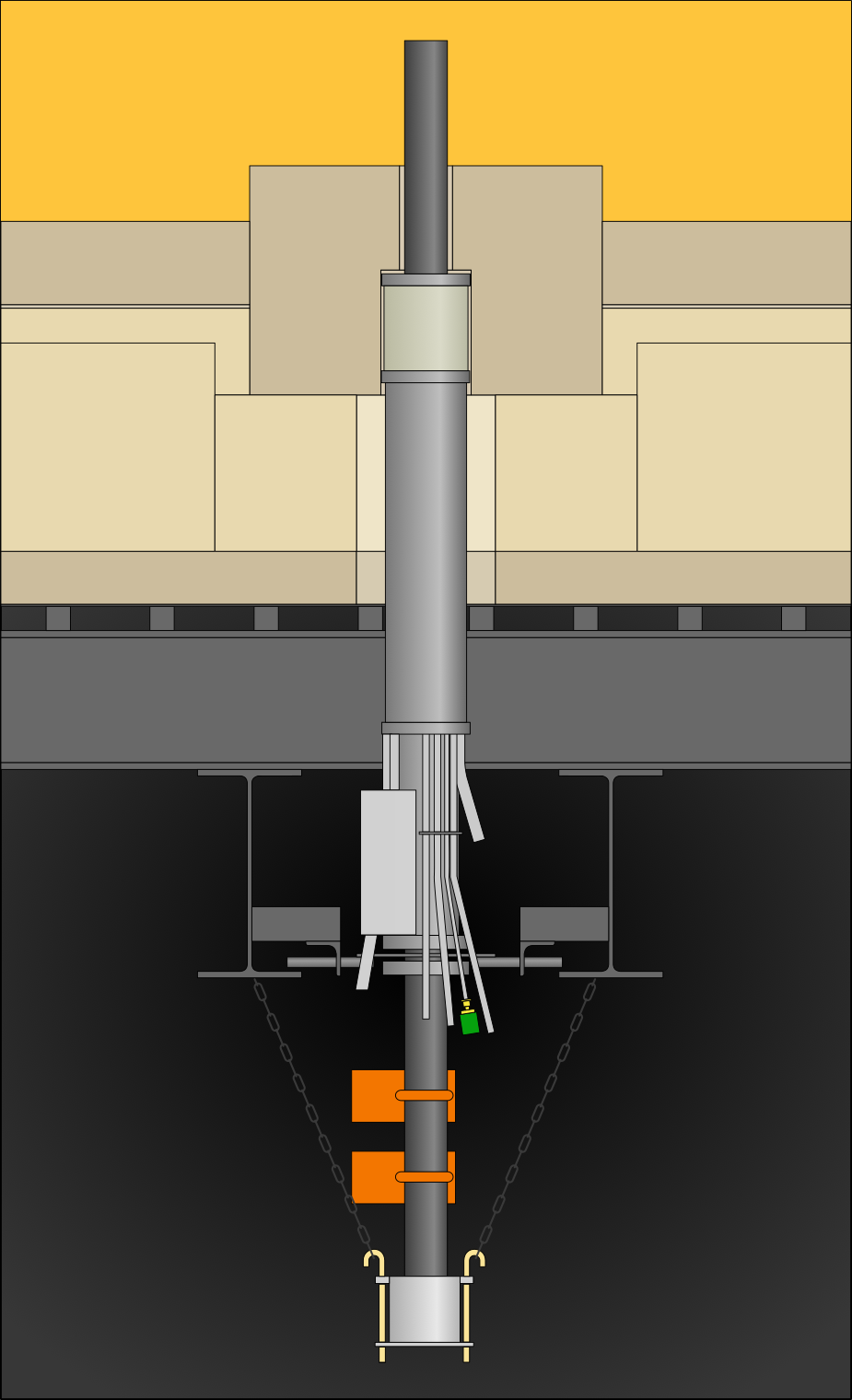

Designs suitable for vertical, angled and horizontal installations

-

Three key designs in lengths and diameters to suit individual requirements

-

Support arrangements to suit individual installations

-

Energy savings of up to 17,000kWh per year per holder

-

Unique thermal insulation of the holder nose, Electroglass holders can extract less than half the amount of heat energy from the furnace than other water-cooled holders

-

High temperature thermal insulation between holder and refractory prevents steep temperature gradients, reducing the risk of refractory thermal shock and cracking

-

Quality and performance proven over many years in furnaces worldwide in a wide variety of glass compositions

-

Electrical isolation between holder and electrode prevents dissimilar metal contact, eliminating the risk of DC voltage related quality issues

-

Designed to operate the entire furnace campaign without need for routine replacement

-

Robust design allows for easy electrode advancing as necessary within a campaign

-

Construction techniques allow for independent movement of internal components during application and removal of cooling when differential contraction may occur

Glass Types

-

Soda Lime

-

Borosilicates

-

Fluoride Opal

-

Potassium Barium

-

E-Glass

-

C-Glass

-

TV and Display Glass

-

Container

-

Cosmetic

-

Tableware

-

Lighting

-

Ovenware

-

Pharmaceutical

-

Automotive

-

Tubing

-

Insulator

-

Glass Wool

-

Fibreglass

-

Float Glass

-

Rolled sheet glass

Molycool (M) Range

-

Designed for vertical, angled or horizontal installation

-

Suitable for use with open or closed water cooling circuits

-

Air pre-cooling to reduce holder temperature prior to application of water cooling

-

Continuous, weld free, cooling coils minimise the risk of thermal shock fracture

-

Require a continuous flow of 4-5 litres/minute of softened water per cooling coil

-

Available to suit 32mm, 50mm, 63mm and 76mm diameter molybdenum electrodes

Horizontal Splashguard (HS) Range

-

Designed for horizontal installation only

-

Suitable for use with open water cooling circuits

-

Open spray cooling circuit increases cooling efficiency around the electrode whilst minimising cooling effect on surrounding refractory

-

Require a continuous flow of 4-5 litres/minute of softened water

-

Available to suit 32mm, 50mm, 63mm and 76mm diameter molybdenum electrodes

Vertical Splashguard (VS) Range

-

Designed for vertical installation

-

Suitable for use with open water cooling circuits

-

Open spray cooling circuit increases cooling efficiency around the electrode whilst minimizing cooling effect on surrounding refractory

-

Require a continuous flow of 4-5 litres/minute of softened water

-

Available to suit 63mm, 76mm and 102mm diameter molybdenum electrodes